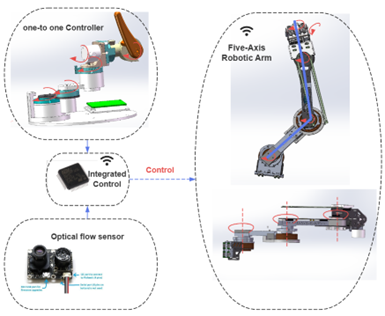

Hybrid Control System Design for a Five-Axis Servo Motor Robotic Arm Based on Optical Flow and One-to-One Encoder Integration

Abstract

This post describes the development of an embedded control system for a five-axis robotic arm, utilizing servo motors, a hybrid control strategy, and PID control with torque feedback.

i.

Responsible for developing an embedded control system for a five-axis robotic arm, utilizing servo motors for the first three axes (resembling a SCARA structure) and enabling pitch and roll degrees of freedom for the last two axes.

ii.

Designed and implemented a hybrid control strategy that integrates optical flow data and one-to-one encoder controller data. This approach leverages the precision of optical flow measurements and the flexibility of encoder-based control, ensuring enhanced motion control performance.

iii.

Developed an advanced motion control algorithm using PID control combined with a dynamic feedforward strategy to achieve precise trajectory tracking and fast response. Successfully achieved a robotic arm repeatable positioning accuracy of 0.1 radians across all joints.

iv.

Integrated torque feedback derived from servo motor current to implement force control, enabling the robotic arm to sense and adapt to external forces during operation. This improved the system’s ability to handle delicate manipulation tasks and ensured safety in human-robot interactions.

v.

Designed and executed comprehensive experiments to validate the control system’s stability, precision, and adaptability under various load and operational conditions. Collaborated on hardware-software integration to implement the hybrid control solution on the physical robotic arm.

vi.

Responsible for data acquisition, analysis, and optimization of the hybrid control system. Combined extensive performance testing with iterative improvements to achieve a balance of precision, speed, and robustness in control.

Pictures

For more information about this theme, you can search the repository.